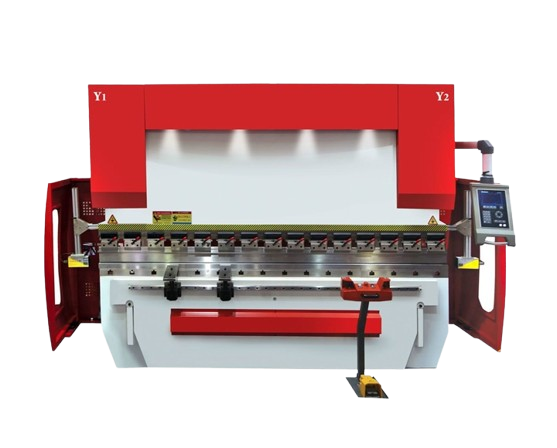

The QC11Y Series Hydraulic Guillotine Shears are industrial-grade metal cutters with all-steel welded structure (vibrating ageing-treated for no internal stress, high rigidity). Equipped with integrated hydraulic system, it smoothly cuts carbon steel, stainless steel, aluminum (6mm-60mm thickness, 1600mm-6000mm width, customizable), with triple-support rails, digital rear stopper (±0.1mm accuracy) and four-edge blades for precision & long life. Adjustable shearing angle reduces deformation, fit for automotive, construction, fabrication. CE/ISO 9001 certified, suitable for small-batch/large-scale production—reliable for high-quality metal cutting.